versace plaster mold | VERSACE MEDUSA FACE MOULD versace plaster mold Our 14-inch mold isn't quite as scary but still pretty badass! Our mold is easy to use for . Giày Louis vuitton chính hãng Pháp, giày dép da cho nam đủ màu, đủ size hàng hiệu. Giày LV cao cấp nhập khẩu nhiều kiểu dáng Sandal, giày da nam, giày lười Auth hàng hiệu. Mua ngay giá tốt nhất.

0 · Versace Silicone Mold

1 · Versace Mold

2 · VERSACE MEDUSA FACE MOULD

3 · Silicone Molds Versace

4 · Medusa Versace 14

5 · Everything You Need to Cast Plaster Details

6 · Amazon.com: Versace Mold

It has been recommended to describe LV geometry as a function of LV mass and RWT. This leads to 4 categories: normal geometry, concentric remodeling (increased RWT), concentric hypertrophy (increased LV mass and RWT), and eccentric hypertrophy (increased LV mass and normal RWT).

Our 14-inch mold isn't quite as scary but still pretty badass! Our mold is easy to use for .

Large Medusa Fondant Molds, Mythical Goddess Cake Decoration Chocolate Silicone Mold, ..99.99.99

Check out our versace mold selection for the very best in unique or custom, handmade pieces ..360.19

.00.00.06.34

.53.42Perfect for designer themed cakes, cupcakes, cakepops, cakesicles or sugar cookies. Best used with fondant, gumpaste or chocolate. Mold size: 5.20 x .Check out our versace silicone mold selection for the very best in unique or custom, handmade .

Hoping to match those details throughout his house, Kevin taught himself how to reproduce the .Check out our silicone molds versace selection for the very best in unique or custom, .

Step: 2. Create the Mold Box. Once the clay prototype is ready, the next step is to create the mold box. The mold box is a container that will hold the plaster while it sets around the prototype.Perfect for designer themed cakes, cupcakes, cakepops, cakesicles or sugar cookies. Best used with fondant, gumpaste or chocolate. Mold size: 5.20 x 2.50 inchesLarge Versace medusa: 1.95 inchesMedium Versace medusa: 1.40 . A plaster mold is a versatile tool in the world of ceramics, allowing artists to reproduce designs with precision and consistency. Plaster is favored for mold-making because of its ability to capture fine details and its moisture-absorbing properties, which help in releasing the clay from the mold. Here’s a step-by-step guide on how to make a . Form the mold. Retrieve your master part. Carefully flatten out the 100% silicone so that it is ½ inch thick. Cover the master item with the 100% silicone—press the 100% silicone into all of the knocks and crannies of the master part.

Juexica 3 Pcs Cup Pottery Molds 2.5'', 3.1'', 3.7'' Plaster Molds Mug Vase Tools with Removable Handle Pottery Shaping Tool Wood Slump Press Mold 3 Size Clay Mold for DIY Ceramic Cup Mug Vase Making. 4.5 out of 5 stars. 7. .99 $ 24. 99 (.33 .33 /Item) FREE delivery Mon, Oct 28 on of items shipped by Amazon.

Versace Silicone Mold

mold. Pour the plaster into a corner so that it will find its own way around the object. Pour until the plaster is at least a one-inch thickness above the object. Once poured, tap the side of the coddle boards with a rubber mallet to release any air bubbles. Then allow the plaster to set. For example, silicone molds are best served by silicone-based mold release agents, while plaster molds work best with wax or oil-based solutions. Additionally, if you plan on making multiple molds of the same object, consider using a reusable release agent that can be re-applied multiple times to extend the lifespan of your mold.

Rubber-plaster mold casting, also known as “plaster casting” or “rubber mold casting,” is a well-established metal casting process that combines the advantages of rubber patterns with plaster molds to produce intricate and detailed metal parts. This technique has been used for centuries and continues to find applications in various . How to Make Plaster Hand Mold: Image credit: Cleverly via YouTube. Step 1. In a bucket, add 3 cups of alginate molding powder and 1 gallon of water, then stir them together for about 45 seconds until thick and well combined, and . Update: Come check out the experimentation that led to my current recipe!. At last, the casting post (that isn’t Hot Glue) is upon us!. As you probably guessed from my Making a 100% Silicone Caulk Mold and the follow-up post, I’ve been happily dabbling in the world of ‘making art desks messy’ for a few weeks now.. As I mentioned in the earlier posts, I’m .

You can use plaster molds to speed up your ceramic making processes. You can produce your own forms with little touches.All of our plaster molds are made of long-lasting plaster. You can use it for ceramic and porcelain casting.

Plaster mold casting, also known as investment casting or lost wax casting, is a process that involves creating a mold out of plaster and then pouring molten metal into the cavity created by the mold. The plaster mold is made by first creating a master pattern, which can be made from various materials like wax or clay. Once the master pattern . What I like about plaster hump molds for clay is that they are easy to make and use. You can make an even, nicely proportioned bowl. If you make a plaster hump mold you are saving money. And, you can make it exactly the shape and size you want. So, before you shell out money buying a mold, try to make a plaster hump mold.You can use plaster for plaster object molds but your concern are separtion for not fussing, ive used vaseline and separating film by factor2 and both work good. Now you need to know if the mold wont catch the main part as a plaster mold is not flexible, so a two or three part mold maybe be needed. design the mold use vaseline for separation. Plaster casting is a process – craft or industrial – in which a metal component is formed in a plaster cavity mold tool that has been cast around sacrificial master copies of a required part, made in plastic foam or wax. Learn more about it here. Get Your Instant Quote. Solutions. Additive Manufacturing .

10. All of this is just too much work and I don't like making plaster molds or having plaster in my studio, but I really want to slip cast some of what I make. I could be snarky, but I won't. The solution is to find someone to make the molds for you. Jonathan Kaplan is a potter, designer, gallery owner, and author of The Mold-Making Manual.WAYS TO USE PLASTER MOLDS This is the second in a series of 3 tips on Plaster and Molds. The last tip was on mixing and pouring plaster. WAYS TO USE PLASTER MOLDS MOLD RELEASE First it is useful to understand mold release. The purpose of mold release is to form a barrier between objects so you can separate them later.

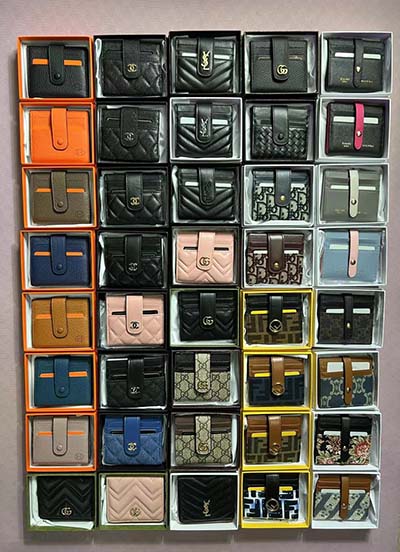

gucci guilty perfume 100ml

The plaster mold will absorb the water in the slip, leaving a layer of clay against the mold's walls. The longer you leave it, the thicker this clay layer will be, so you can control the thickness of your ceramic piece in this way. Removing the Cast. As the ceramic slip molds harden inside the mold, they'll shrink a bit. This makes it easier to .

Strength and durability of a plaster mold. The resistance of the plaster base to make molds is based on several elements that we will define below: Gypsum/water ratio. The resistance and durability of the plaster molds increase while the gypsum/water ratio is increased, always taking into account not to impair the malleability of the preparation. In this work, plaster molds for investment casting, reinforced with short polypropylene fibers, were prepared and their properties and fracture surface features were investigated. Fiber contents ranging from 0.10 to 0.50 wt% were introduced into a powder mixture of gypsum and mullite (ratio of 3:7) as reinforcements in order to prepare thin-walled plaster .

I highly suggest to not hold the mold while pouring to avoid an accidental spill over your fingers. Wax shrinks in volume as it hardens- continue pouring and topping off the mold every few minutes until the reduction ceases. I recommend letting the mold sit for at least 20 minutes to ensure that the wax has hardened.Our hump molds are convex plaster forms that provide a template for slab work. An evenly rolled-out slab of wet clay can be laid over top of the hump and pressed against it. Because plaster is highly absorbent, water will be removed from the clay, and the slab will be easily released. These molds are great for creating functional wares as well .HTVRONT Hand Casting Kit Couples - Plaster Hand Mold Casting Kit with Practice Kit, Gifts for Women & Men Sculpture Hand Molding Kit, Birthday Wedding Valentines Day Gift - for Her & Him. 4.4 out of 5 stars. 28. 50+ bought in past month. .19 $ 25. 19. List: .99 .99. Introduction: Making Plaster Molds For Pottery. Making plaster molds for pottery can be an affordable and practical solution for creating unique and customized ceramic pieces. While purchasing plaster hump molds from stores may be expensive, creating your own molds allows for easy shaping of bowls and opens up a world of creative possibilities. In this .

Check out our plaster molds selection for the very best in unique or custom, handmade pieces from our molds shops.

We stock a huge range of plaster pottery casting moulds made using only the highest quality plaster. With over 100 moulds to choose from we're sure there's something for you . Dutch Molds. Christmas Baubles 3pc. £54.06 £45.05 ex. Vat See all Dutch Molds (4) View Product Quick Buy Dutch Molds. Christmas Bauble Set 3pc. £54.06 .Our goal is produce the finest quality slip cast molds available, using United States Gypsum #1 Pottery plaster. All molds listed on this site are new. Starlite Mold Company Catalogs. The following mold catalogs are available to purchase. All prices are in U.S Currency. All catalogs include a printed price list. Prices DO NOT include postage.

ĢISnet.lv karšu pārlūks (skatīklis) satur brīvi pieejamas topogrāfiskās kartes un citus interesantus kartogrāfiskos materiālus. Publiski pieejamās kartes ir vai nu brīvi lietojamas, vai arī uzskatāmas par bāreņiem (orphan works).

versace plaster mold|VERSACE MEDUSA FACE MOULD